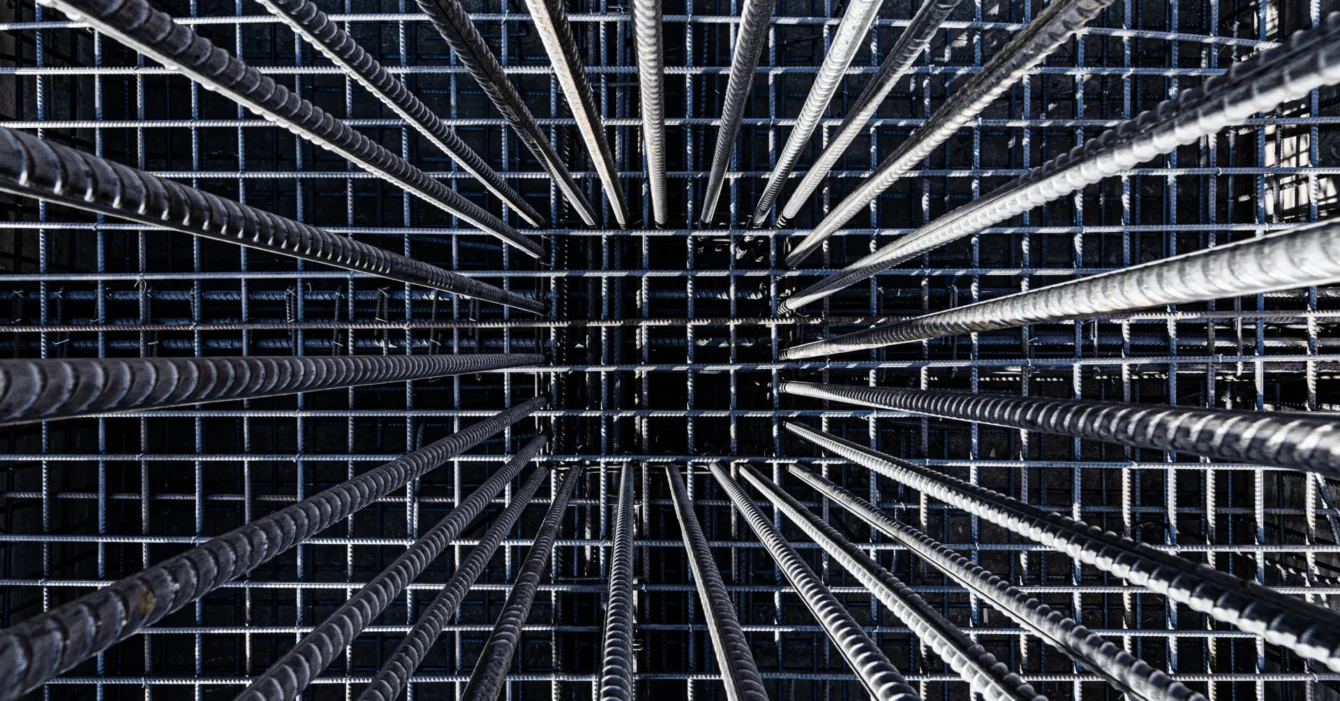

Reinforcement Detailing

Reinforcement detailing is a critical aspect of structural engineering, particularly when designing concrete structures, as it directly influences the strength, durability, and overall performance of a project. At StrucX, reinforcement detailing involves a meticulous process of designing, specifying, and documenting the arrangement of steel reinforcement bars (rebar) within concrete elements, ensuring they meet both structural requirements and relevant building codes.

Key aspects of reinforcement detailing:

Design intent:

The detailing process begins with a comprehensive understanding of the design intent. This includes analysing structural loads, potential failure modes, and the interaction between different materials. The aim is to create a robust reinforcement scheme that effectively manages tensile and shear forces within the concrete.

Material selection:

Choosing the right type and grade of steel reinforcement is essential. Factors such as corrosion resistance, yield strength, and ductility must be considered, particularly for projects in harsh environments or those subjected to seismic activity. The team at StrucX is well-versed in selecting appropriate materials that align with project requirements.

Detailed drawings:

Using advanced software tools such as CADS RC, Bentley Rebar & TEKLA, StrucX produces detailed drawings that clearly depict the placement, spacing, and anchorage of reinforcement bars. These drawings serve as a blueprint for fabricators and construction teams, ensuring that every element is accurately constructed according to specifications.

3D Modelling and visualisation:

3D modelling plays a pivotal role in reinforcement detailing. By visualising the entire structure, engineers can identify potential conflicts with other systems (such as plumbing or electrical) early in the design process. This proactive approach minimises rework and enhances coordination among various trades during construction.

Coordination with other disciplines:

Effective reinforcement detailing requires close collaboration with architects, mechanical and electrical engineers, and construction teams. StrucX emphasises a multidisciplinary approach, ensuring that the reinforcement scheme integrates seamlessly with other design elements, optimising overall project efficiency.

Quality control:

Ensuring the accuracy of reinforcement detailing is paramount. StrucX implements rigorous quality control measures, including peer reviews and automated checks within modelling software, to detect errors or inconsistencies before construction begins. This commitment to precision reduces the risk of costly changes during the construction phase.

Compliance and standards:

Adhering to local and international building codes and standards is crucial in reinforcement detailing. StrucX’s team is well-versed in relevant regulations, ensuring that all designs are compliant and safe. This knowledge not only protects structural integrity but also minimises liability for clients.

Sustainability considerations:

In today’s construction landscape, sustainability is increasingly important. StrucX explores innovative reinforcement strategies that reduce material usage without compromising strength, contributing to more sustainable construction practices.

In summary, reinforcement detailing is a cornerstone of StrucX's approach to delivering high-quality concrete structures. By combining advanced technology, skilled expertise, and a collaborative ethos, StrucX ensures that its reinforcement solutions are both efficient and effective, ultimately enhancing the durability and performance of every project. This attention to detail not only facilitates successful project outcomes but also reinforces StrucX’s reputation as a leader in the field of structural engineering.